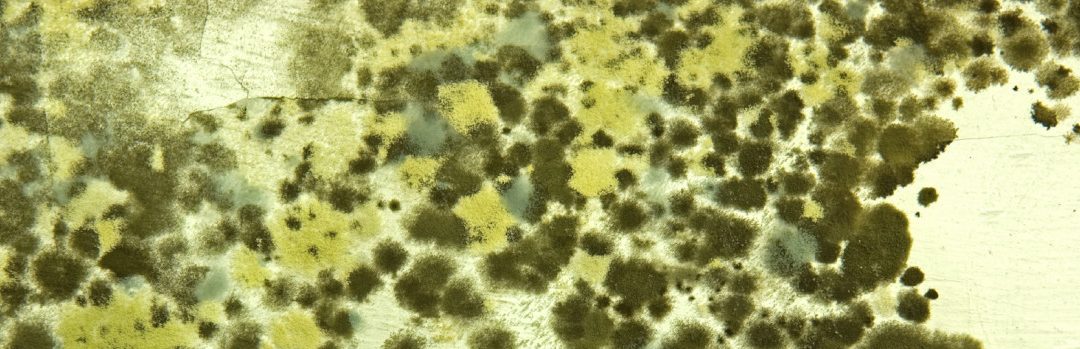

There are many factors that can contribute to mold growth in a building, but HVAC systems are common culprits that are often overlooked. Mold growth in an HVAC system is especially troubling, since it not only affects building occupants’ health near the original source, but can be spread and disperse throughout the building through a forced-air system. It’s a common indoor complaint—mold only needs moisture and a food source in order to thrive.

Mold growth can originate in piping and drain pans, and the EPA recommends that you regularly inspect your system not only for existing mold, but for moisture that may contribute to new mold growth. Check that drain pans are draining properly and aren’t clogged, and make sure that all HVAC ducts and system components are free of moisture.

Preventing Mold Growth in HVAC Systems

The proper design, installation, and maintenance of the HVAC system is essential for avoiding indoor mold, but the best chance you have for preventing mold is controlling indoor moisture. HVAC systems contribute to condensation, so poor design and operation can increase the amount of moisture that is available to support mold growth.

During routine HVAC assessments, the following areas are particularly important to check for mold and moisture:

Humidification/Dehumidification Equipment

Periodically drain this equipment, and try not to allow duct linings to get wet from water spray.

Coils and Drain Pans

If the drain pan isn’t properly maintained, standing water will accumulate and become an absolute breeding ground for mold. Clean drains frequently to maintain healthy indoor air quality. This area of the system is prone to mold because of the condensation that develops when cooling coils dehumidify the surrounding air and cause water to drip into the pan.

Air Filters/Outdoor Air Dampers

Dust and debris that gather on dampers or air filters can have the potential to support mold growth. These should be cleaned and/or replaced regularly.

Remediating Mold in HVAC Systems

First of all, if you know or suspect that your HVAC system is contaminated with mold, do not run the system.

The first reaction is usually to attempt to get rid of the mold with fungicides, biocides and cleaners. But be careful; while these products may kill the mold, you may be leaving behind dead spores that can nevertheless cause indoor air quality problems if they are allowed to spread throughout the building.

If you decide to do the remediation in-house, be sure to use cleaning projects and fungicidal protective coatings that are EPA-registered and labelled for use in HVAC equipment. Workers should take extreme precautions not to spread mold spores to non-affected areas, including wearing protective equipment (masks, gloves), practicing isolation procedures, and using decontamination methods to avoid tracking the mold outside the work area. Another best practice is to use a HEPA vacuum on the cleaned area to avoid spreading non-viable mold spores to other parts of the building.

Another option for dealing with mold in HVAC systems is to hire a professional remediation company. If you go with this route, be sure the company you hire understands the complexities of HVAC system contamination.

Mold in HVAC systems is a common problem because of the nature of the system. But there are steps you can take to help prevent mold growth from becoming harmful. With regular inspection and periodic maintenance, you can keep your HVAC system performing at peak condition while helping to create healthy indoor air quality for building occupants. Give ECMC a call today.