Cooling is the transfer of thermal energy from one medium to another. In industrial applications, cooling can be critical to ensure that processes do not cause equipment or products to overheat. Many cooling applications use water as a medium to absorb heat, because water has a high boiling point and high specific heat. There are many different ways to set up an industrial cooling system, but the three basic types can be summarized by examining how cooling water is used in each system.

Once-Through Cooling System

In once-through cooling, water is pumped from a nearby source, and passes only once through the system to absorb process heat. It is then discharged back into the original source. This source may be a river, lake, ocean, or well.

This design is common where large volumes of low-cost water are available. Additionally, these systems are typical when cooling demand is low to moderate, processes are not critical, and there is room to accommodate large equipment and high volumes of water. One drawback to once-through cooling is susceptibility to disturbance by stochastic water events, such as flooding. Moreover, these systems are being phased out due to concerns about water quality and conservation. A high amount of water is used, and the average temperature change is 5-10 degrees Fahrenheit (3-6 Celsius). Examples:

- Potable Water Systems

- Process Water

- General Service

Closed Recirculating System / Dry Cooling Tower

In closed recirculating systems or dry cooling towers, heat absorbed by the cooling water is either transferred to a second coolant or released into the atmosphere. The word dry is used because the water is never exposed to the air, and as a result, very little water is lost. An automobile engine is a good example of a closed cooling system.

Evaporation is not used in closed recirculating cooling towers. Instead, cool air rushes over a series of small tubes containing circulating coolant. Heat is transferred from the hot liquid inside the tubes to the cool air, resulting in cooling. The coolant is then returned back into the engine. The Average Temperature Change is 10-15° F (6-8° C) and the amount of water used is negligible. Examples:

- Automobile Radiator

- Chilled Water Systems

- Food Temperature Controllers

Open Recirculating System

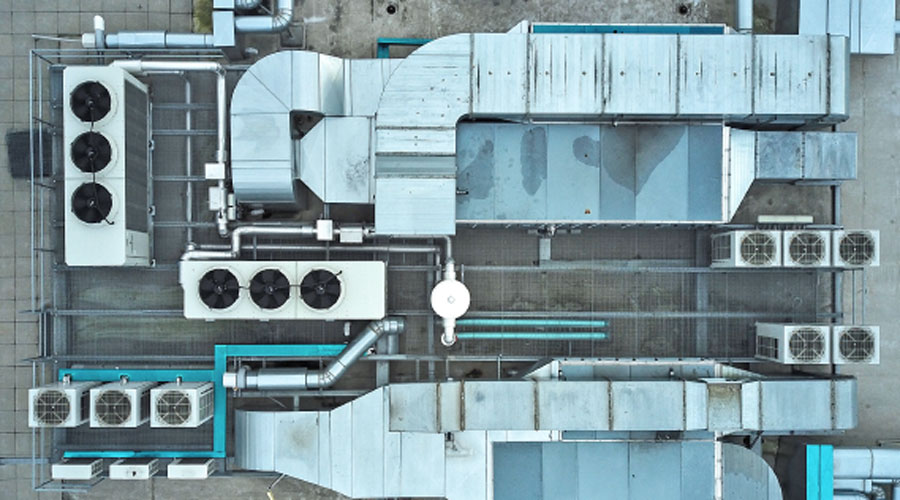

Open recirculating cooling systems or wet cooling towers are the most widely used designs in industry. Just as in closed recirculating systems, the open system uses the same water over and over again. Its most visible feature is the large, outdoor cooling tower that uses evaporation to release heat from the cooling water. Due to the mechanism, this type of cooling tower is also called an evaporative cooling tower. This system consists of three main pieces of equipment: the recirculating water pump(s), the heat exchanger(s), and the cooling tower.

Open recirculation cooling systems feature “wet towers,” where cooling water comes in direct contact with upward airflow. Water from the heat exchanger is pumped evenly over the top deck of the cooling tower. It cascades down and is broken into tiny droplets as it passes through a series of splash plates, called cooling tower fill. This fill can be corrugated plastic sheets, wooden slats, or other devices that increase surface area, thereby enhancing evaporation. As the water droplets bounce off the cooling tower fill, the hottest molecules break away from the water and are carried up and out of the tower as “drift”. The remaining cooled water collects in a tank at the bottom of the tower, called the basin. This cooled water can now be pumped back into the heat exchanger. The Average Temperature Change: 10-30° F (6-17° C) and the amount of water used is moderate. Examples:

- Cooling Towers

- Spray Ponds

Cooling Tower Water Quality

Cooling systems rely on water as a heat transfer medium. This means that water quality becomes essential for continuous operation of any cooling system. Understanding the type of cooling system in your application will help determine the most effective water treatment plan. Learn more about cooling tower water treatment by contacting us.

Contact us

If you have HVAC needs for data centers, join hands with a licensed and insured contractor at East Coast Mechanical. Email: ecmcecmc@aol.com Address: 5133 W Hurley Pond Rd Suite A, Wall Township, NJ 07727 Hours: Monday to Friday 8 AM to 5 PM and Closed Saturday and Sunday.